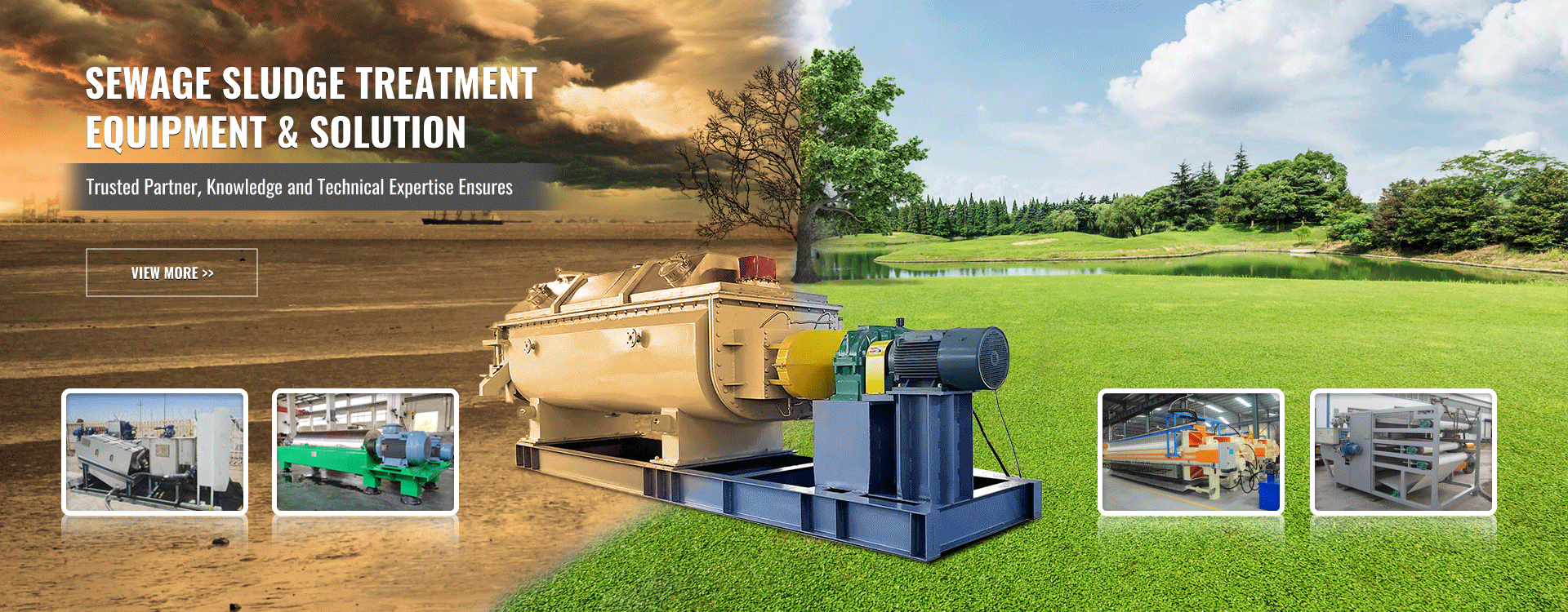

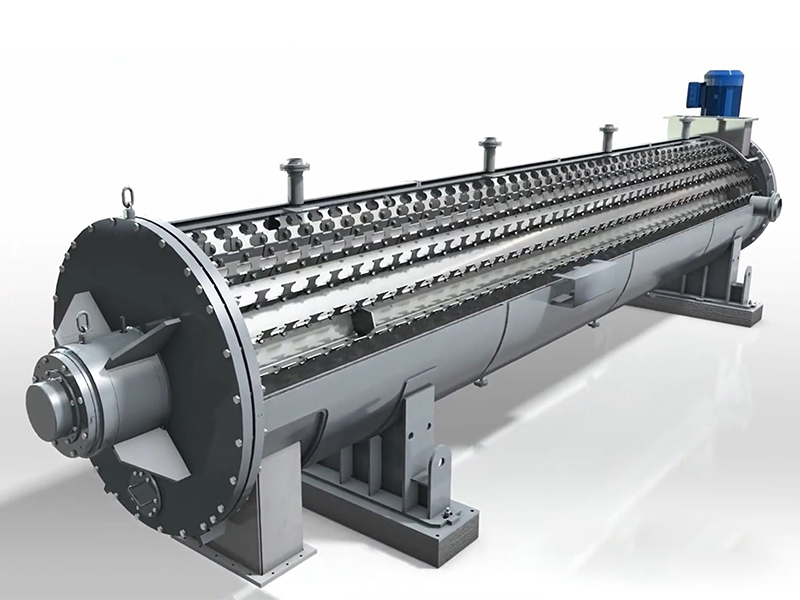

our SYSTEMS

Designed and Built to Meet Your Requirements, Tailor-made to suit your project, tailor-made to suit your facilities.

SOLUTION

-

Put in heart and expertise to work out the ideal solution for you.

-

Providing complete, reliable solutions for compliance and a cleaner environment. Solutions for issues related to the environment, sustainability and cost at any time, any location.

ABOUT US Company Profile

About Xinjieyuan

Guangdong Xinjieyuan Environmental Protection Technology Co., Ltd. professional in: environmental protection equipment research development and manufacturing, water treatment, waste gas treatment, sewage sludge treatment and other fields, is a comprehensive enterprise of environmental protection scientific research, production, sales, has a proven professional operation team and abundant project constructions, with integration, the whole chain, multi-dimensional comprehensive service capabilities.

view more

780 +

2000+ cooperative enterprises

10 years

26 years professional experience

109 +

Professional and technical staff 280+

11700 ㎡

The company covers an area of 30000 square meters

inquiry

For environmental protection, energy saving and emission reduction, water reuse, resource reuse, etc., to provide the exact support!

BLOG & ARTICLES

"DEVELOPMENT TOGETHER, SPARE NO EFFORT" with all our partners hand in hand, create a better future!